Anker Stone (Anchor Blocks) Palace: a miniature neo-Romanesque exterior (and how to cast your own blocks)

- Brandon

- Aug 27, 2025

- 7 min read

First impressions in miniature

Behold: a miniature neo-Romanesque palace with Gothic ambitions, all cast in Anker-style architectural stones. From the stout central campanile to the pencil towers shouldering the roofline, it’s the kind of model that makes you instinctively whisper in a museum voice. The textures are the fun part—silky “stone,” crisp shadowed grout lines, and slate roofs that catch the light like a film still.

If you love miniature exterior dioramas with Romanesque arches, little cloister arcades, and an unapologetically dramatic miniature tower with a conical spire, you’re home. And because you asked for it: keep reading. I’ll give you a full, make-it-yourself walkthrough for casting your own architectural stones so you can build big in small scale—no post-paint weathering required.

Anchor points — a quick history of Anker stones

Before we cast our own, a little context. Anker (Anchor) stones began life in the late 19th century with the Lilienthal brothers—yes, the glider-flying Lilienthals—who experimented with stone building blocks to teach structure and form. Businessman Friedrich A. Richter saw the potential, refined the material into a durable, precisely molded composite, and launched the Anker Steinbaukasten system from Rudolstadt, Germany. The magic was (and still is) the module: pieces follow an exact grid so arches, lintels, voussoirs, and pilasters all interlock like a miniature real-world quarry.

Architects noticed. A kid named Frank Lloyd Wright reportedly played with them; generations of teachers and builders did, too. After a mid-century pause, manufacturing revived, and modern sets continue to ship with that signature red, buff, and slate palette. It’s architectural literacy disguised as play—and a perfect blueprint for the custom-cast stones you’re about to make.

A guided tour of the build

From the left edge, the box-like wooden base declares this is a handcrafted collectible, edged by a thin stone path and sprigs of greengold turf. Tall, rounded windows march in a cool, stately rhythm as a turreted corner rises from stacked courses, each block catching light so the wall reads like real masonry; above, slate roofs break into hips and valleys with nimble highlights. Center stage, a warm-limestone campanile—arcades punched through, a modest arch and shy stair—meets a glowing Romanesque arcade of stubby columns and bead-trim cornices. To the right, a red wing pushes out in buttressed bays, windows grouped in threes, a pencil spire pricking the air while a secondary stair slips into shadow—modular yet theatrical, a miniature campus that turns every angle into a postcard.

Inspirations — from the big world to the small

This piece wears its lineage proudly. Think Alfred Waterhouse’s Natural History Museum in London with its rhythm of round arches and banded masonry; add a dash of the Smithsonian Castle’s romantic silhouette; and sprinkle the massing logic of H. H. Richardson’s Romanesque revival (all that chunky gravity). In miniature, those references get distilled to crisp module sizes, repeatable arches, and hierarchical towers—forms you can actually build because the blocks play by the same rules that real stone does. That’s the power of a good system.

Artist tips — Make your own magic:

(You can buy genuine Anker stones directly from the manufacturer—highly recommended if you want to jump straight to building. But today we’re rolling up sleeves and casting your own architectural stones so you can design any module you dream up.)

You’re not just making “blocks.” You’re minting architecture—modules that click into arches, towers, and galleries like a pocket-sized city kit. Let’s give your workshop a quarry.

Mini shopping list:

LEGO bricks for mold boxes (everyday hack) — or acrylic mold walls with rubber bands.

100% silicone caulk + cornstarch (“Oogoo”) to make quick, cheap molds — or platinum-cure silicone if you want pro longevity.

Masters for your blocks: 3D prints, laser-cut styrene shapes, or borrowed blocks from an existing set (with permission!).

Dental stone / Hydrocal (gypsum Type III) — or standard plaster of Paris if that’s what you have.

Pigments: red iron oxide, yellow ochre, raw umber, black iron oxide.

Precision scale (0.1 g resolution) — or a set of measuring spoons for approximate batching.

Sieve (200–400 mesh tea strainer works) for de-lumping pigments and sand.

Fine play sand (sifted) for texture — or marble dust (calcium carbonate) for a silkier finish.

Dish soap (drop or two as surfactant), distilled water, and pipettes for accurate dosing.

Vibration helper: old electric toothbrush or phone set to “buzz” to chase microbubbles.

Mold release: light petroleum jelly, thinned with a touch of mineral oil — or talc/baby powder dusting.

Safety kit: nitrile gloves, dust mask/respirator (P100 if sanding), and eye protection.

Quick wins

Pick a module and stick to it. Try a 6 × 12 × 24 mm “brick” (height × width × length). All other pieces derive cleanly from that.

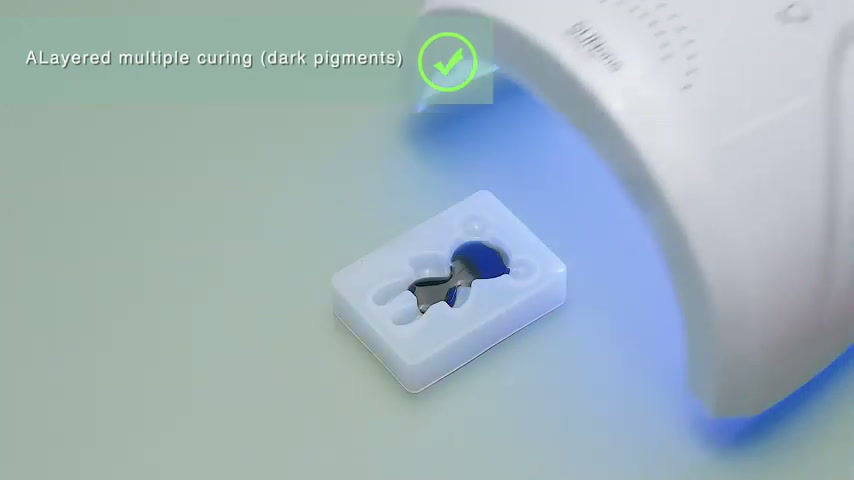

Tint at the mix, not after. No weathering or paint required—pigment goes straight into the gypsum.

Break bubbles fast. Tap the mold on a book or buzz it with a toothbrush.

Demold early, cure slow. Pop at 25–35 minutes while the cast is firm but not brittle; let it harden overnight.

Keep a color notebook. Write down pigment ratios for your red, buff, and slate tones—you’ll thank yourself on batch two.

Deep dive (numbered steps)

Planning & scale notes

Decide your model scale (e.g., 1:87 HO, 1:100, or 1:120 TT). Then select a module that feels right in hand. I like 6 mm height because arches look graceful without getting too tiny to handle.

Draft a module table:

Full block: 6 × 12 × 24 mm

Half: 6 × 12 × 12 mm

Quarter: 6 × 12 × 6 mm

Plate/slab: 3 × 12 × 24 mm

Voussoir/arch wedge: thickness 6 mm, subtend 22.5° or 30° per piece (12 or 8 pieces to a semicircle).

Tolerance matters: target ±0.2 mm. Gypsum barely shrinks; molds do the precision work.

Bones (base structure)

Rip a wooden base about 10–13 mm thick with a shallow rabbet for a grass mat. Seal the wood so moisture from the casts doesn’t warp it.

Draw a grid on the base that matches your module length (24 mm). Your buildings will go up laser-straight with almost no measuring.

Base colors & materials (pigment recipes): You’re tinting the material itself—no paint later. Start small, note ratios by percent of powder weight:

Anker Red: 1.2% red iron oxide + 0.3% raw umber.

Buff Limestone: 0.6% yellow ochre + 0.1% raw umber.

Slate Grey: 0.6% black iron oxide + 0.1% ultramarine (optional cool note).

Mortar/Trim Light: 0.2% raw umber (nearly white).Pro tip: iron oxides are potent. Err light; you can always darken next batch.

Casting the stones (the core recipe)

Make masters. 3D print at 0.12–0.16 mm layer height, or cut and laminate styrene to exact size. Lightly sand mating faces.

Build a mold box. LEGO bricks on a baseplate: quick, square, and reusable. Leave 5–7 mm of silicone around every master.

Silicone mold:

Budget — mix 100% silicone caulk with cornstarch (about 1:1 by volume) + a splash of mineral spirits to loosen. Work fast; it cures quick.

Pro — mix platinum-cure silicone per manufacturer ratio (often 10:1). Degas if you have a vacuum chamber; if not, pour in a thin ribbon from high.

Mold release. Wipe a whisper of petroleum jelly on masters so your mold lives to cast another day.

Gypsum mix: weigh 100 g dental stone to 30–32 mL water (0.30–0.32 water/powder). For texture, add 5–10% sifted sand or marble dust to the powder. For color, add 0.2–1.2% pigment by powder weight.

Mixing order: pigment → dry blend with powder → add to water. Let it slake for 1 minute, then stir for 60–90 seconds until creamy. Add one drop of dish soap to pop bubbles.

Pour & vibrate. Drip into the thinnest cavities first. Tap, buzz, or gently shake the mold.

Demold at 25–35 minutes. Pieces should feel like firm cheddar: not sticky, not crumbly. Lay flat on a wire rack.

Cure 24 hours (or 2 hours in a 60 °C / 140 °F oven) before building.

Shaping specialty pieces

For arches, cast a ring of wedges and a keystone. A simple printed protractor helps you keep the radius consistent.

For cornices and stringcourses, cast long plates and sand a tiny chamfer (0.5–1 mm) along the edge for that crisp highlight.

For spires, stack successively smaller squares and finish with a cone turned from cast stock (a pencil sharpener makes a surprisingly good micro-lathe).

Assembly

Build dry when possible—the friction fit is half the joy. If you need glue, use thinned PVA (roughly 1:1 with water) brushed sparingly on hidden faces.

Keep courses level by checking every few rows with a small machinist square or the edge of a card. Misalignments compound quickly at this scale.

Photo tips & backdrop ideas

Backdrop: charcoal or umber paper for classic gallery vibes; or a soft, gradient poster board curved into a sweep.

Angle: slightly overhead, three-quarter view to reveal depth and the diorama’s edges (a clear “this is a crafted object” cue).

Aperture: f/8–f/11 on APS-C or equivalent for front-to-back crispness; focus a third of the way into the scene.

Troubleshooting (problem → fix)

Bubbles on edges → stir slower, add one drop of dish soap, and vibrate the mold longer.

Weak or chalky casts → raise powder ratio (toward 0.30 w/p), switch to dental stone, or oven-dry longer.

Color mismatch between batches → weigh pigment precisely; keep a swatch tile for each color.

Warping plates → demold later, or press between waxed boards with a book as it cures.

Sticking to mold → use a better release or dust with talc; for Oogoo molds, reduce cornstarch next batch.

Safety reminder: Work with ventilation, wear gloves, and use eye protection. If you sand casts or handle powdered pigments, wear a P100 mask and keep the shop tidy—future you will breathe easier.

Closing — until next time in the Small World

From Lilienthal experiments to Richter’s factory and right onto your bench, Anker-style stones prove that good modules make great architecture. This palace of spires scratches my “build a campus” itch every time I look at it—and now you’ve got a recipe to pour your own quarry, color it at the mix, and stack a skyline without a single paint step.

Tell me in the comments: which detail would you build first—campanile, cloister, or the cheeky pencil spires? Share your own cast-stone creations with #smallworldminiatures, and if you like deep dives like this, hop onto the newsletter so you never miss a new tutorial or print release. See you on the tiny jobsite.

Hashtags:

#SmallWorldMiniatures #MiniatureArchitecture #AnkerStones #Steinbaukasten #ArchitecturalToys #ArchitecturalModel #ScaleModel #HOscale #MiniatureDiorama #MiniaturePhotography #CinematicLighting #DIYMolds #SiliconeMold #Hydrocal #DentalStone #GypsumCasting #PigmentedPlaster #IronOxidePigment #ModuleBuilding #ModularDesign #RomanesqueRevival #RichardsonianRomanesque #GothicRevival #NaturalHistoryMuseumLondon #SmithsonianCastle #DomesAndSpires #ToyArchitecture #MakerCommunity #CraftTips #TinyArchitecture

Comments